|

About Fred V Fowler

Catalogue Pages

|

|

|

Checking System and

SPC Improve Gage Studies

|

Fairfield

Manufacturing, October 1996

To attain the

high precision part quality needed by gear manufacturers,

ISO 9001 certification is not always enough. In the case of

Fairfield Manufacturing Company, Inc., QS 9000 plus a range

of industry specifications, in addition to the special needs

set by individual customer companies, are more the quality

norm for this largest independent North American producer

of a broad range of loose gears and complete power transmission

assemblies.

Currently, the

company produces more than 10,000 different part numbers totaling

about two million gears ranging in size from 1 to 60" in diameter.

|

|

| Gage

Repeatability and Reproducibility |

|

For Fairfield,

which has been able "to reduce costly, post-production inspection,

the major challenge has been to increase our on-line measuring

capabilities so that we can have optimum control of our manufacturing

process in order to meet the multi-level goals of our customers,"

says Dan Phebus. Director of Quality. - In turn, we make our

customer assembly operations more reliable because the gears

conform precisely to their own design drawings. We believe

that GR&R is the key to reducing both our own and other users'

variations."

By increasing

its measuring capabilities, Fairfield has made major gains

in preventing variations through better process control, significantly

reducing rejects by correcting the manufacturing process beforehand.

Highly accurate instrumentation became necessary to succeed.

Through its Production Part Approval Process (PPAP), Fairfield

bolstered its GR&R program. "We had to verify the process

statistically. That would allow us to meet the rigorous tolerances

we not only set for ourselves but which were critical for

our customers," Phebus says.

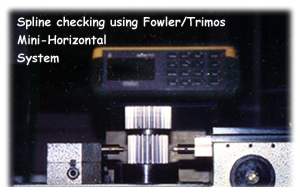

The key instrument

first acquired in 1992 was a Fowler/Trimos Mini-Horizontal

Measuring System which enables Fairfield to measure

both internal and external gear parts accurately in one pass.

It replaced "mikes and pins," which caused gage errors of

25% or higher "under ideal conditions," he adds, More recently,

five more Mini-Horizontals have been acquired.

|

| In

House Studies to Process Control |

| Phebus

says the company had conducted an intensive in-house study on

gaging errors. For example, it found that measuring a part with

a total tolerance of 0.0018. made with 3"- 4" micrometers and

calipers. primarily hand-held tools, showed a gage error of

51.7 %, with column-mounted "mikes and pins" a 33.7% error. |

| |

However,

when using its new Mini-Horizontal Measuring

System only a 7.4% error was evident. |

| |

| This is why, Phebus

says "today's measurement capability has to exceed production

process capability. We have transformed our operation from post-production

inspection to on-line process control, reaping the twin benefits

of better quality improvements and cost- reductions." |

|

| How

this was accomplished was due in large part to an idea of Ron

Gellenbeck, the company's chief tool designer, who suggested

putting the Fowler/Trimos instruments on movable carts adjacent

to the production line. This was a superior and quicker way

to get results than by trucking over the finished gears to an

inspection laboratory. "We did it all on-line and thus could

immediately detect variations. Then we could alter the process

to gain the uniformity that was our goal." |

| High

Volume Measuring... |

Fairfield's basic

business is gears and power transmission systems for OEM customers

manufacturing off-highway and construction equipment, mining,

railroad, agricultural, industrial and material handling equipment

of all kinds. This makes big demands on its products' accuracy

and conformance to design specifications. "We have a high volume

of gears to be measured and sorted according to gear size," says

Gellenbeck. "They are boxed and shipped by classifications, and

some of our customers require reverse classification. This means

that the smaller gear pitch diameter needs a larger code number.

In contrast to all other instruments on the market, the Fowler/Trimos

Mini-Horizontal System can handle the correct size code in

reverse order.

In addition, he

explained, the stable base of the Mini-Horizontal units complemented

the movable cart system Fairfield had devised to per- form the

on-line measurements prior to heat treating the gears and the

grinding operations.

|

| Six

primary benefits of the new system have resulted: |

- Obtaining a

true process control technique.

- Saving substantial

amounts of time over post-production inspection.

- Reducing customer

assembly time.

- Significant

dollar savings for the process by reducing rejects and producing

faster verification of part sizes.

- Better human

relations in the plant, because measurement operators like

the ease of using the system, encountering less fatigue

than before.

- The new ability

to measure both externally and internally. The latter advantage

was achieved by Fairfield technicians who expanded the utility

of the Trimos instrument and its Sylvac probe by devising

new anvils to measure gear sizes up to 12"in diameter.

|

| Ruggedness,

Reliability and Accuracy! |

| Gellenbeck adds

that the original selection of the instrument depended heavily

on its 0.00006"accuracy and the fact that the anvils were removable

and thus could be replaced with ball-type or cylindrical pins

to measure pitch diameters, The system has a Sylvac

1" travel probe and a digital readout display box. A direct

two-way RS-232C data output allows connection to a printer.

"With this gage,"

concludes Phebus, "we detect variations quickly and simply

and are sure we're not getting false signals about our process."

The company is continuing to refine its SPC program and improve

the accuracy of its instrumentation, since they are mutually

dependent for ultimate product precision.

|

ami

|

|