Wyler Zerotronic Sensors Delivers Wafers Faster

Precise determination

of inclinations is a critical requirement for Seagate Inc. (Bloomington,

MN), a vertically integrated builder of hard disk and tape drives

for data storage.

|

|

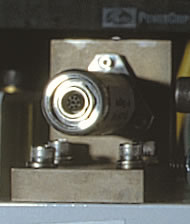

Mounted

on this grinder spindle, the

Wyler sensor system has helped Seagate Inc. increase the efficiency

of its wafer

grinding operations.

|

An outside vendor manufactures

wafer substrates by a unique hot-pressing process and then supplies

them to Seagate, which builds up its recording head structures on

them. Seagate's own ceramic-grinding operation on the finished wafer

is extremely sensitive. The 4.5-inch square wafers each worth thousands

of dollars are ground down to 1,250 microns. If the sensitive wafer

grinder used in the process is not set at precisely the required

angle, the work becomes too costly, and time-consuming adjustments

are required. This might take as many as 3 hours. Also, the labor

costs for highly trained technicians becomes unsupportable.

Seagate's technology

produces a variety of hardware and provides business intelligence,

and storage and network management services. But, at the heart of

its activities is the ability to make zero-defect recording heads

assembled at plants in various domestic and overseas locations.

When the company purchased

Fred V. Fowler Company's (Newton, MA) new Wyler Zerotronic sensor

system, it substantially increased the efficiency of its tightly

controlled and fine-tolerance processing operations. This digitized

inclination sensor fulfills the critical function of accurately

measuring the relative angle between the chuck holding the wafer

and the grind wheel axis.

"The spindle angle",

said Mike Kwilinski, a manufacturing engineer at Seagate, "is

important because of the type of grinding used to produce the wafers.

We must use a minimum spindle angle that best complements the hardness

of the self-dressing grinding wheel. One of the keys in setting

up the grinders is to measure a precise angle between the grind

spindle and the work chuck."

|

| Closeup

of the Zerotronic Mounting. Cable has been removed for clarity. |

If the spindle angle

is too small, the wheels won't break down and will dull. When a

60-pound force on the machine is reached, the grinder stops and

manual unloading is required for rectification. If the angle is

too large, the wheel breaks down too quickly.

"With wheels costing

$1,100 each, the ability for them to function correctly becomes

a big factor". "The spindle angle also determines wafer

thickness uniformity, which is absolutely necessary" said

Kwilinski.

He described the long and complex operation of adjusting a grinding

machine, which takes it out of production for 3 hours and requires

the attention of highly trained personnel. The 3-hour savings for

each of the six or eight trials needed for each experiment is a

critical factor in managing Seagate’s wafer production system.

"The Zerotronics

sensors basically let us know where we're at, and this is a vital

bit of information we need to set up the grinders correctly and

to know where the wheel spindle is in space." said Kwilinski.

The wheels are 11 inches in diameter with a band of abrasive 1/8-inch

wide. Tolerance for every point on every wafer is ±8 microns. The

wafers measure 4 1/2 inches square and 1 1/4 millimeters thick.

It takes about 45 days to produce a wafer and requires more than

100 operations.

|

SYSTEM

BENEFITS

- Increased

efficiency of tightly controlled

and fine-tolerance processing operations.

- Complete

measurement accuracy.

- Savings

of 3 hours.

|

The device handles both

small angles with a high resolution as well as large angles. A temperature

sensor mathematically compensates for changing environmental conditions,

which improves measurement results.