|

|

|---|

|

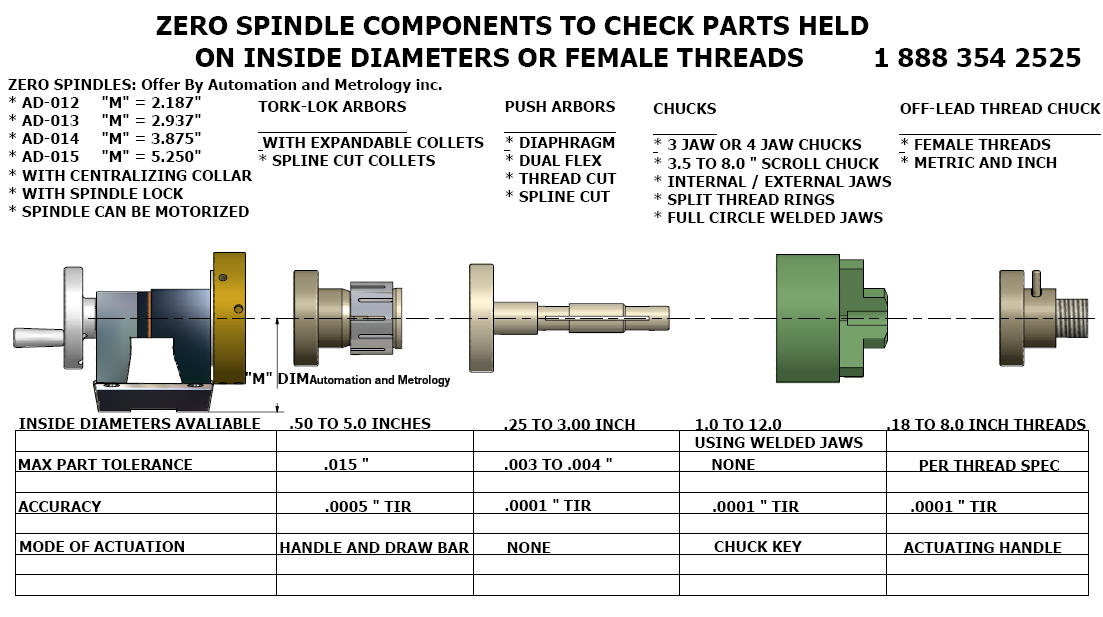

Zero Spindles are an accurate way to check parts for

runout, T.I.R., etc. The Zero Spindle accuracy is .000020"/.0005mm total

runout before adding holding devices which allow you to have an accurate

platform to start your measuring process. Zero spindles are used with

Diaphragm Push Arbors, Dual-Flex Push Arbors, Tork-Lok Arbors, Three and

Four Jaw Chucks, Magnetic Chucks, ODC Collects, 1 & 5C Collets, and face

plates. |

|

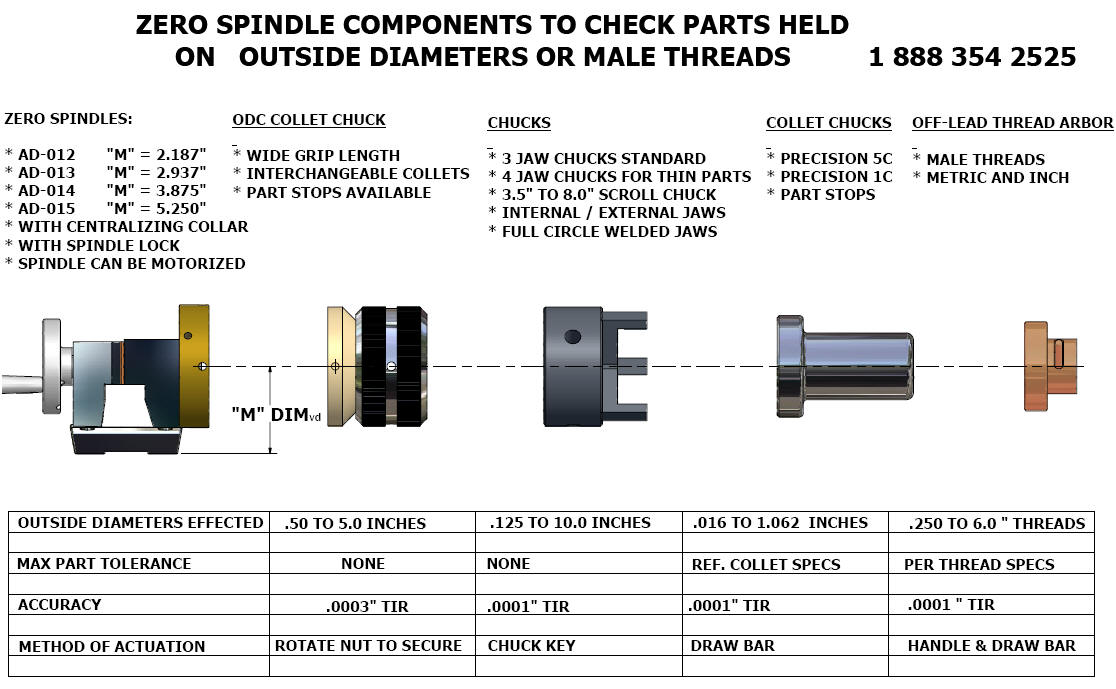

The GSG Zero Spindle offers various methods of holding a part on the outside feature during rotation. The charts show the 4 major methods collet, 3-4 jaw chuck, and external off lead lock. These methods can be combined with various measurement methods and provide the user with a robust and repeatable way of inspecting ovality, runnout, diameter and true position of round parts. |

|

|

|

|

|

| |

|

|

|

|

|

| Zero Spindle 5C - Collet | |

|

|

| Zero Spindle 1C - Collet | |

|

For Inside Diameters or Female Threads - Zero Spindle PDF Link Data Sheet

|

|

|

|

|

| Zero Spindle | |

|

|

| Zero Mag Plate | |

|

|

|

|

|

|

THE ZERO SPINDLE SYSTEMS The GSG Zero Spindle System is accurate (T.I.R less than .000020"), rugged,

versatile, and economical. It can chuck on a wide array of parts, ID or OD. The OD features ODC collets, 5C collets, or 3 jaw chucking capability. GSG

can further enhance the Zero Spindle System through the use of extended jaws for

All of the above accessories can be mounted horizontally or vertically and,

when used with indicators, can be mounted so as to swing in/out to check runout,

All configurations can be ordered with conventional masters to recalibrate

the system or be used with special part masters, which simulate the actual part

being A complete inspection system for checking concentricity, squareness and

roundness. With the many accessories manufactured exclusively for the |