Calibration

Internal ISO Quality Systems

Our

quality system has established lines of management

control with defined levels of responsibility to

assure the effectiveness of our policy. We employ

the best talent, machinery, and inspection equipment

for our manufacturing lines. This builds and

coordinates a high quality atmosphere to ensure

customer satisfaction. Together as a “TEAM”,

Universals management team and employees are

strongly committed to delivering only the best

quality product; “ON TIME” and “EVERY TIME".

ISO

9001:2000 Certified: The scope of Machining and

Packaging of Medical Components and Instruments.

ISO 13485:2003 Compliant: The scope of Machining and

Packaging of Medical Components and Instruments.

FDA Compliant to FDA part 21 CFR 820 for the scope

of Machining and Packaging of Medical Components and

Instruments.

12.0

Calibration

12.1 Purpose

To establish a

standard procedure for the calibration of all

Concentricity Gages.

12.2 Scope

All Concentricity

Gages used to measure, test, inspect, or otherwise

examine items to determine compliance with set

specifications. This procedure also applies to Gages

returned to Universal Punch Corp. for routine

calibration.

12.3 Definitions

Calibration

– A procedure performed under specific conditions that

establishes the relationship between values measured and

known values derived from applicable standards.

Recalibration

– A systematic check and adjustment of the accuracy and

precision of a particular item performed at prescribed

intervals.

Verification

– A check for proper “zero” and limited confirmation of

an items accuracy by comparing it to a known standard.

Runout

- (Measured in Full Indicator Movement or “FIM”) – The

measurement of surface variation that occurs relative to

an axis of rotation. It is the total amount of movement

(FIM) on an indicator after on full revolution of a part

that is rotated about its datum axis. It may be measured

parallel (outer surface) or perpendicular (face) to the

axis.

12.4 Materials and

Conditions required

Granite Surface Plate

with floor vibration isolators

Calibrated gage Test Pin traceable to N.I.S.T. (size

depends on Gage being tested)

Electronic Gage Head or Gage Probe (LVDT) with Amplifier

at 10:1 ratio

Cleaning solution and Lint-free Cloth

Temperature controlled environment at ±2° with ½° change

per hour.

12.5

Special precautions

Verify that the

calibration status of all equipment being used is

current.

Do not use abrasive stones to remove imperfections on

the Gage Roller surfaces.

Use caution when removing dirt, oil and other foreign

substances when cleaning Gages.

12.6 Tolerances (Runout)

12.6.1 .0002” Max. for

standard Gage assembly (Black Models)

12.6.2 .000070” Max. for precision Gage assembly

(Gold Models)

12.7 Procedure

Verify that the

identification on the Gage is distinct and in agreement

with the Calibration History or the customer PO number.

(New Gage / Recalibration).

Carefully examine the

Main Rollers and the Top Roller for nicks, burrs, rust

or other signs of mishandling or wear. Replace the Main

Roller or Top Roller if necessary.

Carefully clean all

exposed surfaces removing all foreign substances and

particulate matter.

Move the Indicator

Carrier to the right to provide sufficient clearance to

insert the test pin into the Gage without interference.

Using the appropriate

holder, mount the measuring instrument to the Indicator

Carrier holder on the Concentricity Gage. Ensure that it

is properly placed and rigidly held by the Holder /

Indicator Carrier assembly.

Verify the runout to

be measured and place the appropriate calibrated test

pin into the Concentricity Gage between the Main Rollers

and allow the Top Roller to clamp it securely.

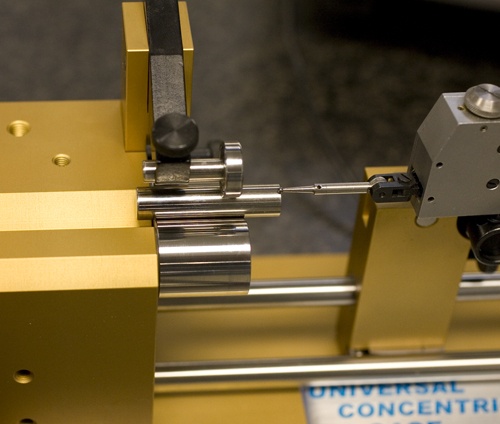

Move the Indicator

Carrier holder with the measuring instrument assembly

and bring the measuring instrument into position to

measure the Calibrated test pin. This is a point

approximately ¼ “ from the end of the Main Rollers

aligned with the centerline of the test pin in the

vertical direction as shown in Figure 15a.

Zero the measuring

instrument according to the manufacturers instructions.

Using the drive system

of the Concentricity Gage, rotate the test pin a minimum

of three revolutions to establish seating in the Main

Rollers. Rotate the Drive Knob slowly and note the

readings (FIM) from the measuring device.

Repeat Rotation

a minimum of 3 times to rule out any obvious incorrect

readings.

Figure 15a. Calibration Set-up. Model

B-10 shown.

Storage and Handling Active and inactive equipment shall

be maintained, stored and handled in such a way as to

preserve its accuracy and fitness for use. Equipment

that is out of calibration or damaged shall be removed

from use.

Calibration Proceedure Document |